WhatsApp)

WhatsApp)

Certified Concrete Technician Procedures and Policies Manual 405 Portland Cement Concrete Plant Inspection 802 Random Sampling 803 Contractor Quality Control Plans Appendix B AASHTO Test Methods Knowledge of mix design plants materials and

US Portland Cement Industry Plant Information Summary Competitive Materials Report World of Concrete February 4–7 2020 Las Vegas NV 25 ExhibitsOnly Admission Concrete Sustainability Hub Purchase Design and Control of Concrete Mixtures LATEST NEWS PCA Forecasts Moderate Cement Consumption and GDP Growth Annually in Next Two

Divisions Engineering Division Technical Services Materials Bureau Forms and Manuals Engineering Division Office of Technical Services Materials Bureau FormsManuals Daily Concrete Batch Plant Report 031998 BR 317 Aggregate Tests For Portland Cement Concrete Plant Self Consolidating Concrete Mix Design Qualification

Handbooks and Manuals Handbooks and manuals are ACI documents that provide tools and guidance to the practitioner on applying design construction and inspection standards Handbooks typically contain charts tables and examples to facilitate design of concrete structures formwork and reinforcement detailing

The Quality Manual is flexible in design and can be customized to follow the quality processes of a specific concrete producer In developing these guidelines the essential elements of Quality Management Standards of ISO 9000 were followed and this guideline was written so that they are pertinent to

PDF On Apr 1 2016 Akshey Bhargava and others published Design of Bag Filter for the Control of Dust Emissions for a Cement Plant Find read and cite all the research you need on ResearchGate

Project Advisor for a new cement plant in New Zealand Assistance with process design for a new mini cement plant in New Zealand Project Advisor for a new cement plant in Honduras Assistance with Performance Tests for a new 3100 tpd Polysius kiln at Cementos del Norte Honduras 2008 Project Advisor for a new cement plant in Nigeria

Concrete Study Manuals Concrete Certified Field Technician Manual PDF Concrete Certified Field Technician Recertification Manual PDF Concrete Plant Quality Control Technician Manual PDF Concrete Mix Design Manual PDF Aggregate Technician Certification Program Requirements Aggregate Certified Testing Technician Course PDF TDOT

Safe Design of Portland Cement Plants Safe by Design Inherently Safe hazardous conditions and the risk of injury and illness resulting from its use or operation A process plant equipment or product that has purposely incorporated in it certain physical andor chemical characteristics that noticeably reduce Safe by Design A Personal

Usually the mix design water cement ratio is twice the wc ratio required for hydration The extra water the water of convenience is needed to provide workability Hydraulic Cements Hydraulic cement is a material that sets and hardens when it comes in contact with water

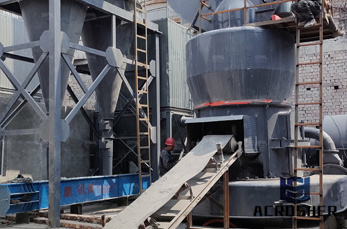

Cement Review Operation Handbook cement plant design manuals Rotary Kiln Design Handbook For Cement Process Plant The cement rotary kiln produced by Machinery has simple and solid structure stable operation convenient and reliable control of the production process fewer quickwear parts high quality of final products and high running rate so that it is the equipment for cement plants to

Cement Plant Design Handbook January 2019 This handbook has been superseded by the Cement Plant Operations Handbook 7th Edition Fully revised and updated with improved content the new Sixth Edition of the Cement Plant Operations Handbook is now available Covering some 300 pages the cement

ACI Manual of Concrete Inspection Reported by ACI Committee 311 ACI 3111R07 ACI SP207 PREFACE This manual is intended to guide assist and instruct concrete inspectors and others engaged in concrete construction and testing including field engineers construction superintendents supervisors laboratory and field technicians and workers

Website http © All rights reserved

Welcome The Materials Certification Program is offered by the Materials Division of the Virginia Department of Transportation VDOT and offers individuals training and certification in the following areas Aggregate Properties Asphalt Field Asphalt Plant Level 1 Asphalt Plant Mix Design Level 2 Central Mix Aggregate Plant Concrete Field Concrete Plant Pavement Marking Slurry Surfacing

January 2019 This handbook has been superseded by the Cement Plant Operations Handbook 7th Edition Fully revised and updated with improved content the new Sixth Edition of the Cement Plant Operations Handbook is now available Covering some 300 pages the cement

manual to record the State specification requirements for several classes of concrete A more indepth discussion of the test procedures can be found in the Design and Control of Concrete Mixtures published by the Portland Cement Association and the Standard Specifications for

Concrete Mix Design Section 4 Treated Subgrade and Base Courses Anchor i Item 276 Cement Treatment PlantMixed currently designates three classes of cementtreated flexible base based on 7day unconfined compressive strength Class M is intended for use with flexible pavements Class L is intended for use with rigid

The manual was developed for plantproduced precast concrete members or precast prestressed concrete members manufactured by the process of pretensioning posttensioning or a

WhatsApp)

WhatsApp)