WhatsApp)

WhatsApp)

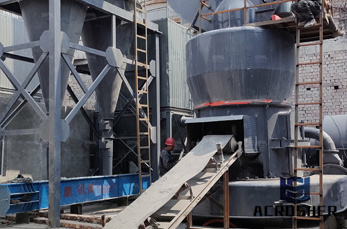

Vertical Shaft Kiln is used for the calcination of cement clinker limestone bauxite and other vertical kiln manufactured by ZK group has the advantages such as modern design new technology environmental protectionenergy saving higher machanization and automaticity etc

In a shaft kiln the limestone dolomite moves counter flow to hot gases in the shaft This gives shaft kilns the lowest fuel consumption of any type of calciner The shaft refers to a vertical vessel where the calcining takes place

Vertical shaft kiln technology is approved by National Council of building material Govt of India and Cement Shaft Kiln is modern day answer for cost effective production and a boon for the developing countries VSK is only technology available world wide for small

were proposed to mitigate various negative phenomena experienced in the operations of vertical kilns Keywords Vertical shaft kiln Operation strategy investment Burner Firing Profile 10 Introduction The vertical shaft lime kilns have been shown to posses a lot of potentials in the lime industry Okonkwo etal 1991

Exporter of Vertical Shaft kiln plant Calcined Lime Kiln Plant Lime Plant Lime Kiln offered by Kinc Mineral Technologies Private Limited Vadodara Gujarat

vertical shaft kiln cement manufacture Cement kiln Wikipedia the free encyclopedia Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement

5 Vertical Shaft Kiln 6 Storage silo for clinker 7 Ball mill for cement grinding 8 Storage silo for cement Figure 1 Process Flow sheet of Cement Manufacturing situated on the top of the kiln Kiln Operation The vertical shaft kilns are fed with raw mix of appropriate composition in the form of nodules The

VSK Vertical shaft Kiln Cement Plant Ashoka Group offering Vertical shaft kiln cement plants high efficiency cost effective energysaving Cement plants based on VSK technology designed and developed by our efficient and dedicated team of various individuals

We are a reputed firm engaged in the manufacture of premium quality Vertical Shaft Kiln For Cement Plant These kilns are plants made up of ordinary Portland cement These mini plants have small production capacities and are installed in different specifications The raw materials used for the manufacture of these plants are limestone clay cokebreeze gypsum and laterite

Jul 02 2008· CLINKER FROM ROTARY OR VERTICAL SHAFT KILN Dear Sirs what is the difference between a clinker produced in a rotary kiln and the clinker produced in a vertical shaft kiln I know that the disadvantages of the VSK kiln are the inclusion of ash in the clinker the problem with homogeneity of heat distribution the low production

Jul 02 2008· CLINKER FROM ROTARY OR VERTICAL SHAFT KILN Dear Sirs what is the difference between a clinker produced in a rotary kiln and the clinker produced in a vertical shaft kiln I know that the disadvantages of the VSK kiln are the inclusion of ash in the clinker the problem with homogeneity of heat distribution the low production

offers 2907 vertical shaft cement kiln products About 97 of these are cement making machinery A wide variety of vertical shaft cement kiln options are available to you such as free samples There are 2901 vertical shaft cement kiln suppliers mainly located in Asia

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year and cement kilns are the heart of this production process their capacity usually defines the capacity of the cement plant

Our standard linings for vertical shaft kilns consist of wearresistant hotface linings and thermally efficient backup linings This combination provides lime producers with an economical and tough refractory lining that can withstand the thermal and mechanical challenges present in a vertical shaft kiln

39 rows· Our standard linings for vertical shaft kilns consist of wearresistant hotface linings and

Selecting the Proper Lime Kiln Technology Lime is a key industrial mineral used as a chemical additive by many industries The industrial facilities that utilize Lime in various forms are metal ore processing metallurgy steel paper pharmaceuticals sulfur removal and water treatment

The Vertical Shaft Brick Kiln technology developed in China is an energyefficient environmentfriendly and economicallyviable means to produce quality bricks Given below are the main factors that have favour this technology • Extremely low pollution level • 40 to 50 per cent energy savings when compared to local clamps and 30 to 40 per

WhatsApp)

WhatsApp)