WhatsApp)

WhatsApp)

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Module: 5 Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 162 Animation Lime stone or chalk and clay are crushed into gyratory crusher to get 25 cm

Clinker: compositional parameters. Chemical parameters based on the oxide composition are very useful in describing clinker characteristics. The following .

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

The Republic Cement Group, Meralco and key officials from the municipal government of Norzagaray, Bulacan, recently performed the groundbreaking rites of a project ...

The O''Hagin patented tapered, lowprofile attic vents offer the best ventilation solution for composition shingle, slate and shake roof applications.

Design and Control of Concrete Mixtures, 16th edition: Media Type: Print: Every industry has one outstanding reference book, and for concrete it is Design and Control ...

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden.

Aims to improve cement and concrete and its uses, and raise the quality of construction. Page includes industry news magazine.

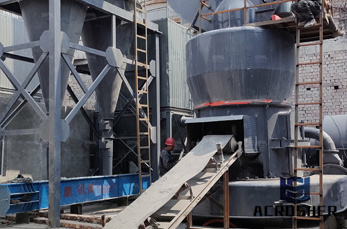

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Calcium aluminate cements are cements consisting predominantly of hydraulic calcium aluminates. Alternative names are "aluminous cement", "highalumina cement" and ...

In properties, White Portland cement differs from ordinary Portland cement only in its light colour. However, the details of its formulation and manufacture are quite ...

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Metso Minerals Process Technology AsiaPacific, Brisbane, Australia email: metso

Heavyduty performance 2 Ideal for both prehomogenisation and buffer storage of raw materials, FLSmidth stacker and reclaimer systems have an impressive track record ...

ColorView® ColorView® makes selecting and coordinating siding, roofing, and trim easier and more fun.

Overview of cement milling, gypsum addition and dehydration.

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

See our Powerpoints on tire incineration. What is "Tire Derived Fuel" and why is it dangerous? As of 2003, about 290 million tires are discarded in the every ...

Ordinary Portland Cement is prepared by a fullyautomated, dry manufacturing process using state of the art technology under strict quality assurance at all stages of ...

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

WhatsApp)

WhatsApp)