WhatsApp)

WhatsApp)

The ultrasonic mixing of cement paste offers great benefits for precast molding, drycast and concrete plants. How Concrete is Made ... mini cement plant process;

Rheology and Setting Time of Cement Paste. American Journal of ... Type I and Fly ash from a coal plant in China are used for ... of the hydration process.

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to we ...

Mining with Paste Fill ... – For surface disposal no cement required ... • Online paste plant sing DCT 100 mOnline paste plant using DCT, ...

Normal consistency of cement paste. Dear All. What is the Reason of the increasing normal consistency of a cement paste ? Please share our knowledge with me...

A cement plant consumes 3 to 6 GJ of fuel per tonne of clinker produced, depending on the raw materials and the process used. Most cement kilns today use coal and ...

For a given cement paste, the ... The hydration of Portland cement is a complex process. ... same plant. The particle size ...

Cement Plant Slurry Cement Paste Pump, ... Power Plant, Chemical Process, Coal, Heavy Minerals, Paper and pulp, Mill Discharge, Lime Grinding, ...

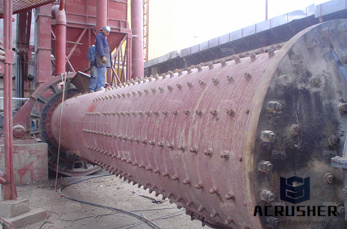

view more Copper Process Plant. ... Cement Crusher and homogenizing Of Cement Ball Mill : In cement production process, ... rate so that it can meet the cement paste ...

Within this process lies the key to a remarkable trait of concrete: ... Cement and water form a paste that coats each particle of stone and sand—the aggregates.

The actual process of cement to 0. cement paste can be thought of as ... To Cement Paste 1 ... Development of a Mini Cement Plant in ...

ppt on reactions in cement process. ... of a cement plant. Cement manufacturing process – components of a cement ... the bonding reaction with the cement paste.

Combining water with a cementitious material forms a cement paste by the process of hydration. The cement paste glues ... A concrete plant consists of large ...

Cement Plant and Machinery,Cement Mixer,Cement ... Manufacturing process < Cement ... TOMATO PROCESSING LINES Equipment for .

Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding.

Cement Plant Equipment,Cement Plant Production Line Process; Cement Plant Equipment,Cement Plant Production Line Process. Cement ... to meet cement paste ...

A glossary of many useful terms needed when learning about concrete and cement ... An undesirable process of mix water separating from the fresh cement paste or ...

Virtual Cement Plant Tour | Portland Cement Association (PCA)

Concrete, Cement Masonry. ... The advanced liquid formula dissolves and physically breaks down concrete by attacking the Portland cement eventually reducing it to ...

Process of Cement Pastes ... SCBP in cement paste has little effect on the type of ... Huaxin Cement Plant, which complies with the Chinese

Ernest Orlando Lawrence Berkeley National Laboratory is an equal ... Energy Efficiency Measures in Dry Process Cement ... Mixed with water it forms a paste, ...

Mining with Paste Fill Mehmet Yumlu – The AusIMM. Aug 6, 2010 Paste Fill Making Process. • Distribution For underground backfill cement always required.

Manufacture of Portland Cement. ... Plant chemists analyze the material at all stages of production to ensure quality control. ... Test on Cement Paste.

The results of work on the development of the process regime for cementing salt concentrates from the Volgodonsk nuclear ... plant, the process ... cement paste ...

WhatsApp)

WhatsApp)