WhatsApp)

WhatsApp)

Thermalbased power plants can produce electricity from coal or other fuel sources The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption Coal fired power plants while producing power require a lot of water and produce a lot of pollutants like ash and CO2

According to the US Energy Information Administration 27 gigawatts of capacity from coalfired generators is to be retired from 175 coalfired power plants between 2012 and 2016 Natural gas showed a corresponding increase increasing by a third over 2011 Coals share of electricity generation dropped to just over 36

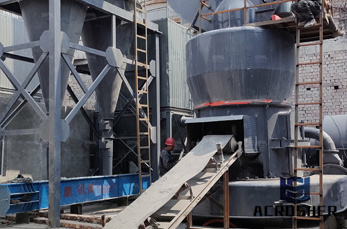

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill where the grinding table and some heavy rollers pulverizes the coal to

Nov 29 2019· has unveiled plans to invest around €110 million to install a biomass power plant at a paper mill facility in Germany The plant will have an electrical output of 20MW and a thermal firing capacity of 87MW as well as supplying heat to UPM''s Hürth paper mill and helping to

Aug 18 2018· Coal mill Primary air fan Thermal power plant engineering pulverized coal fired boiler HINDI PULVERIZED COAL FIRED BOILER WHAT IS PF BOILER DOMINATOR OF THERMAL POWER PLANTS

Furthermore at least two coal mills were common or planned for this mode of operation This was also logged accordingly in the operating and process control technology Firing is what matters In the BadenWuerttemberg coalfired power plant it was the operating engineers'' task to specifically target the load limits of a powergenerating unit

Jul 06 2017· Dust accumulated in a chute completely unseen and caused the fire Often it is the hidden dust that causes the devastation carrying the explosion or causing secondary explosions throughout the plant Oil Fire Hazards Coal dust is not the only cause of

Sep 01 2018· CHESTER Kimberly Clark plans to invest 150 million in its Chester site in transforming its cogeneration power plant from a coalfired one into one fueled by natural gas The Chester mill

Feb 20 2017· Originally Answered What are the applications of ball mill in coal fixed power plants Ball mills are used primary for single stage fine grinding regrinding and as the second stage in two stage grinding circuits According to the need of customers ball mill can be either wet or dry designs

Coalfired power plant Coal is a flammable black or a brown sedimentary rock made of organic carbon in addition to hydrogen oxygen sulfur and nitrogen Coal also is the most used fossil fuels for producing electricity as we use coal power plant for producing around 40 of the world''s electricity

what is mill in coal fired power plant puravankarawestend As an example consider these facts for typical coal fired power plant of capacity 500 MW Around 2 million tons of coal will be required each year to produce the continuous power Coal combustion in the boiler requires air

Feb 21 2017· Ball mills are used primary for single stage fine grinding regrinding and as the second stage in two stage grinding circuits According to the need of customers ball mill can be either wet or dry designs Ball mills have been designed in standa

about coal mill in power plant mills for coal power plant cakekraftin thermal power plant mill coal elevation Fuel saving in coalfired power plant with Improving Coal Pulverizer Performance and detailing this equipment in a directfired coal burning system Combustion Engineering 783RP BowlMill Coal operation of the power plant

Xcel Energy has plans to close its coalfired Comanche plant from which New CFI a unit of Evraz has a direct transmission link to its steel mill in Pueblo Colorado Evraz said that unless the solar deal is signed it will move its operations which have been in Pueblo since the late 19th century out of state

Nov 17 2012· Coal mill pulverizer in thermal power plants 3 pulverizermill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder

A fossil fuel power station is a thermal power station which burns a fossil fuel such as coal or natural gas to produce fuel power stations have machinery to convert the heat energy of combustion into mechanical energy which then operates an electrical prime mover may be a steam turbine a gas turbine or in small plants a reciprocating gas engine

Pindo Deli Pulp And Paper Mills Coal Fired Power Plant Karawang 180 likes · 3 talking about this EnergyUtility Get Price Coal fed power plants IBERMAROS IBERMAROS has a long experience in rebuilding rollers and tables of vertical mills in the coalfired power plants either on

List of power stations in Maryland Jump to navigation Jump to search Coalfired Name Location Type Capacity Luke Mill Power Plant Luke Maryland Coal 65 Verso Corporation 1958 Morgantown Generating Station Newburg Maryland Coal List of power stations in the United States List of wind farms in the United States

A typical MPS89 pulverizer found in many coalfired power plants Courtesy On the left is a typical Alstom Power mill on the right an MPS89 of similar capacity These two mill types

In coal fired power plant coal mill is used to grind pulverize and dry coal before the coal is transmitted the boiler coal mill used in boiler plant miningbmw Coal Feed Systems For Boiler and Coal Milling Plant Kruppolysis Coal Mill Oct 21 2013 · Coal mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them into

Jul 20 2016· Power plant basics The coal pulverizer Shad Edwards PULVERIZED COAL FIRED BOILER WHAT IS PF BOILER DOMINATOR OF THERMAL POWER PLANTS Duration PULVERIZER PLANT COAL MILL

In coalfired power plants coal mills p are used to pulverize and dry to coal before it is blown into the power plant furnace

How Coal Power Plants Produce Electricity The steam is then piped to a turbine The high pressure steam impinges and expands across a number of sets of blades in the turbine The impulse and the thrust created rotates the turbine The steam is then condensed and pumped back into the boiler to

This is all controlled by the coal mill or pulveriser and its associated feeder equipment Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output For coalfired power plants the response time of the coal mills is critical for the overall reaction time to changing demand

WhatsApp)

WhatsApp)