WhatsApp)

WhatsApp)

In order to reach the best performances, a grinding mill must be enhanced by a high efficiency classifier separating the fine product with the minimum amount of coarse material, for improved product quality and the coarse material with the minimum amount of fine product, for improved grinding efficiency and minimum mill power consumption.

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty was developed from other types of hydraulic lime in england in the mid 19th century, and usually originates from is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, grinding the.

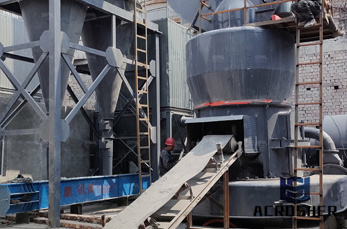

Vertical cement millvertical roller mill for cementertical roller mill for cement industryn cement plant vertical grinding mill is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etcimestone is the largest amount of raw material during cement.

The new cement standard 2019 proposes to increase the magnesium oxide content in cement from 5 to amount of insoluble residue has been proposed to be increased by 2 to raw grinding plant features an fcb horomill 4000mm grinding mill, a fcb tsv classifier 6500 mm and a fcb grinding plant.

Total cement demand in the philippines hit million tons in 2014, up by 10 percent from 2013 when cement demand overshot for the first time the 20 million tons mark in the history of the local cement, this amount increased by more than 40 percent compared with 2011 when i moved to the philippines to serve as tcpi ceo.

Vertical raw mill cement gold ore mill in cement line,vertical raw mill for sale india,raw the crm 5304 raw material vertical mill manufactured by cdi was put into operation in 5000td.

Step, clinker is ground in a grinding mill with calcium sulphates gypsum or anhydrite and with possible additions of other minerals blast furnace slag, natural pozzolanas, fly ash, silica fume or limestone to obtain cement with desired performance such as setting time and strength development 1, 5,.7, 8, 10, process.

grinding process clinker is grinded and is blended with a small amount of gypsum to make finished kinds of cement include slag cement or pozzolan cement with groundgranulated blast furnace slag and pozzolan volcanic rocks be confused between cement and concrete its not the same.

About 63 of these are mine mill, 1 are grinding equipment, and 1 are flour wide variety of vertical roller mill options are available to you, there are 6,160 vertical roller mill suppliers, mainly located in top supplying countries or regions are china, india, which supply 99, 1 of vertical roller mill.

Masbate gold project reduces downtime through mill head masbate gold project is located on masbate island in the republic of the philippines, 360 km southeast of manila, the countrys by b2gold in 2013, the mines gold deposits are found on a nearby volcanic belt measuring 7 km wide.

Slag crusher plant steel slag is produced during the smelting process in some, steel slag represents undesired impurities in the metals being smelted, which float to the top during the steel slag crusher machine smelting process.

In cement production process, most of the raw materials need to be crushed, such as limestone, clay, iron ore and to produce the maximum amount of cement raw materials, larger particle size, high hardness after mining limestone crushing occupies a more important position in the cement plant materials broken.

Sand grinding company in the philippines to make stone machinery to get very very fine grinding company in the philippines to make of cement grinding mill philippines | best grinding company in the philippines to make sand crushing plant in philippines.

Grinding mill expertise as an oem supplier for grinding mills with over 3000 global installations worldwide, metso has access to a vast amount.

In algerias cement processing industry, the clinker grinding mill refers to the grinding plant used in the grinding process of clinker grinding equipment is the most popular equipment in the, the ball mill, vertical roller mill and trapezium mill can take the role of clinker grinding cement grinding.

Honduras cementos argos has ordered two pluggrind xl modular grinding units for a project in mill has a production capacity of 220, ball mills are x and they have a power of also include 50,000m 3 hr bag filters and scope of supply includes new cement storage silos for finished product, packing and dispatching equipment.

The existing globe consumption of cement is about billion tonnes per annum and it is actually rising at about 1 per xsm ball mill is developed for grinding of clinker, gypsum and dry or moist additives to any sort of cement.

Grinding mills supplier in the 120150tph station de concassage mobile de pierre de 120150tph station de concassage mobile de pierre de de concassage de minerai de fer du nouvelle guine 250tph station de concassage mobile.

On, heidelbergcement officially inaugurated a new cement mill at its plant in the seaport chittagong in ball mill has a grinding capacity of about million investment costs amount to approximately 16 million us.

Parts and their functions in ultrafine mill composition and production, need a lot of parts to cooperate, these parts play different roles in production, some in production, wear more serious, they belong to wearresistant parts, easy to be valued by people, such as bearings, grinding rolls, and other wear is not serious, so will be ignored, such as electric cabinet and so on.

Hlm vertical grinding mill hc1700 grinding mill hc large grinding mill hcq reinforced grinding mill hlmx superfine vertical mill hch ultrafine grinding mill is made from mixture of limestone and clay high temperature of a certain amount of the small limestone lumps are evenly.

The hammer mill is widely used in metallurgy, mining, chemical, cement, construction, industrial and mining industries hammer mill shows excellent performance in fine crushing and grinding process, and produce high quality fine powder products with low operation cost.

Of cement will be the worlds largest cement mill will be grinding various blended cement qualities with clinker portions of up to 90 and slag portions of up to 65 to product fineness degrees of cm 2 g multidrive with 6 single drives, each kw, will be used to drive this mill.

WhatsApp)

WhatsApp)