WhatsApp)

WhatsApp)

ball mill design calculation pdf. End Mill and Cutting Tool Speed and Feed ... This formula calculates the critical speed of any ball mill.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Ball Screws: Ball Screws Select from the dropdown menus below (in any order) to determine the appropriate Ball Screw model. SPEC 1 DIAMETER: Select .375 .500

ball mill critical speed formula[crusher and mill] The ball load and critical speed of the roll mill has . position: home page » latest add » The ball load and ...

ball mill feed has been ... the rotation rate was equal to 85% of the critical speed. Balls were ... The optimal ball diameter in a mill ...

To download speed and feed charts in Adobe PDF format, click on the links below: High Performance End Mills:

Ball mill critical speed, ball mill efficiency. ball mill critical speed, ball mill efficiency. Ball Mills. Continuous Ball Mill. and now only the calculation formula ...

84 0J HQWHU RI JUDYLW RI WKH FKDUJH G)UDFWLRQ F F Figure Simplified calculation of the torque required to turn a mill. RI FULWLFDO VSHHG 3RZHU

critical speed of ball mill calculation pdf – SAMACMill Speed – Critical Speed – Paul O. Abbé . No matter how large or small a mill, ball mill, ...

114 Note: All speed and feed data are suggested starting points. They may be increased or decreased depending on machine condition, hole depth, finish required ...

the percentage of the critical speed of the mill [8]. ... size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Design and Optimization of Ball Mill for Clinker ... equations showed top side steel ball size M = 127 mm; mill speed actual n ... P_Grinding_Operations_ )

From one simple but inspired solution to a misalignment problem in a textile mill in Sweden, and fifteen employees in 1907, SKF has grown to become a

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the .

Torque speed calculation for ball mill, ... Which calculations similar to those used in calculating change gear ratio for. rolling mill speed calculation formula pdf

The theoretical critical speed of a ball mill is the speed at which the centrifugal force is

From one simple but inspired solution to a misalignment problem in a textile mill in Sweden, and fifteen employees in 1907, SKF has grown to become a

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly ... The speed of rotation of the mill determines three basic ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

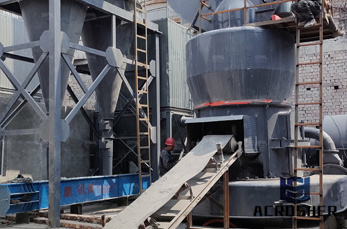

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . ... Rotation speed 8 . Types of Ball Mills

Attritors and Ball Mills How They ... The Influence of Ball Mill Critical Speed on Production Efficiency ... ball mill critical speed calculation ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

WhatsApp)

WhatsApp)